(Wastewater Treatment Systems)

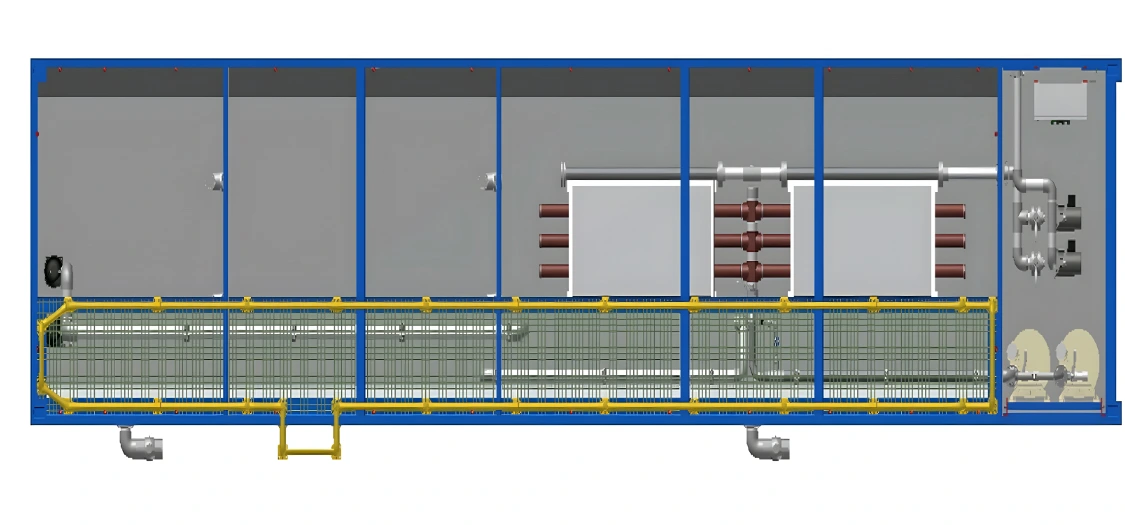

BioMatch MBR

BioMatch MBR is a cutting-edge wastewater treatment containerized system from Enviromatch Inc. that provides a capacity range starting from 125 and up to 500 m3/d (depending on the effluent requirements).

This innovative unit is the core treatment part of an integrated Wastewater Treatment Plant (WWTP), utilizing advanced membrane technology to efficiently remove contaminants and impurities from wastewater. Designed to meet the highest industry standards, BioMatch MBR offers sustainable, reliable, and cost-effective wastewater treatment solutions.

Trust Enviromatch Inc. to provide your facility with the best-in-class wastewater treatment solutions.

Request a Quote

Standard features

Two (1 duty/ 1 standby) regenerative air blowers, complete with swing check valve, inlet filter/ silencer & safety valve

One electrical oil-free air compressor with a storage tank

Two (1 duty/ 1 standby) Chlorine dosing pumps

Two (1 duty/ 1 standby) self-priming pumps

One control panel, All equipment wiring terminated to the control panel

Overhead lighting

Epoxy-coated steel supports

Galvanized steel and PVC interconnecting piping

Electrical

Siemens PLC-based control panel

Power supply: 460V / 3ph / 60Hz

Programmable time delays and set points

Weintek HMI colored touchscreen

VFD pump and blower motor control

Status indication lamps and switches

IP54 enclosure with disconnect and Interlocking rotary handle

120V/60Hz control voltage

Instrumentation

Air Compressor pressure switch

Air Compressor pressure gauges, 2 ½” dial size

Air Blower pressure gauges, 2 ½” dial size

Permeate water Paddlewheel Flowmeter

Diaphragm differential pressure sensor

Valves

Galvanized steel aeration piping

PVC low-pressure piping

Pneumatically actuated C.I. butterfly valves

Available options

380-415V/3 Ph/50Hz power supply, 220V control panel

230V/3 Ph/60Hz power supply

Equalization tank level float switches

Equalizing pump(s) motor starter with overload relay

Equalization tank Ultrasonic level transmitter

Feed pH controller/sensor

Feed ORP controller/sensor

Feed TDS / conductivity sensor

Custom designed units

Operating and performance specifications

| Model | Max flow (GPD) | Max flow (M3/D) | BOD (mg/L) | T-N (mg/L) | T-P (mg/L) | TSS (mg/L) | Dimensions (LxWxH) in (mm) |

|---|---|---|---|---|---|---|---|

| BMM-01 | 33000 | 125 | 300 | 45 | 15 | 350 | 6060 x 2400 x 2900 |

| BMM-02 | 66000 | 250 | 300 | 45 | 15 | 350 | 12200 x 2400 x 2900 |

| BMM-04 | 132000 | 500 | 300 | 45 | 15 | 350 | 12200 x 2400 x 2900 |

– Multiple units of the same size shall be used for larger flows.

– For applications with different influent characteristics, customized models will be specified.

– Dimensions and other technical data may be changed without our responsibility.

– Please contact us for any upgrade.

Related featured projects (view all)

Related projects

Ministry of Defense

Landfill Leachate Treatment

Middle East Can Company Recycle Project

Dammam Paper Mill Recycle Plant

View allDo you need the BioMatch-MBR

Wastewater Treatment Containerized System?

Send us a message or call our office with any inquiries you have.